We celebrated the first anniversary of completing the layout... by taking bits of it apart!

After much consideration, I decided that the last remaining diamond crossover had to go. The crossover was causing some rolling stock to jump when passing over it and some derailments / uncouplings. Also due to the complex layout at this junction there was quite a kink in the tracks.

I'm not a fan of diamond crossovers, I own half a dozen and when this layout was designed, I reluctantly incorporated three of them into the design. Following the recent modifications to the rear fiddle yard, this left just the one crossover at the front for the run-around loop. In reality after a year of using the layout, we've never used the run-around and it's unlikely that we ever will. I find myself manually detaching locos on the inner loop, running forwards over the points and then reversing into the turntable sidings to swap locos, so the void left by the crossover is being filled by an electric uncoupler. The extra points involved in the run-around loop also creates issues when running tender-first out of the turntable, there are frequent derailments over the second set, so changing these to a half curve should eliminate this problem also.

To do this job properly, boards one and two needed to be set up and joined together properly to ensure that the tracks stay aligned across the board joins.

First job was to start lifting the tracks...

On a non-scenic layout, this would have been dead easy, not so when there's ballast involved.

(The two workmen actually now look like they're doing something!)

With the tracks lifted, I also needed access to the points on the inner loop. A second semaphore signal is being installed so I need another electric trigger. The points have a ready-made dead section that makes this really easy to do.

In the foreground of this picture you can see a piece of wood that was added to compensate for the warping that occurred during the initial build of the layout, this lifted the track sufficiently enough to make it level.

And while butchering the tracks on this board, it made sense to fit another set of triggers to the points at the end of the level crossing, these will provide automation to the two colour light signals, meaning that all the signals on the layout will be automated.

Second pair of points gone, half curve installed and track refitted...

The new, streamlined appearance...

Some tidying and ballasting to be done, which is not my department!

Looking down the layout, the track is now much straighter than before, which should improve reliability even further...

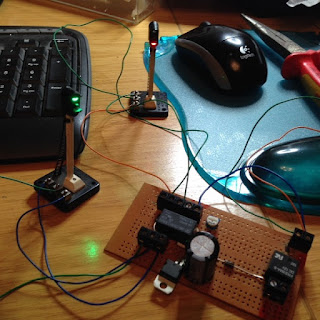

The second semaphore to appear on the layout. The plan is to automate the home and distant signals using the existing semaphore and the newly installed trigger. As the train passes over the points, the electric current generated will operate a capacitor discharge based timing circuit, this will throw both signals to red at the same time. Once the timing circuit has finished (the capacitor has discharged) the home signal will then revert to green, with the distant signal reverting to green once the next trigger circuit, fitted after the other semaphore, finishes its cycle.

That's the theory anyway.

Also due for some attention, the scenery along the back of the turntable yard. The paint and PVA has flaked quite badly so has been patched ready for repainting.

Once the ballast has been laid and dried, the next job will be to flip the board and rewire underneath, removing all the redundant points wiring and installing the timer circuits for the signal controls.

More to follow...